Are you here because you strive for a perfectly printed design? Well, you are in the right place. Indeed, whether it is a metal, plastic, glass, or printing on other surfaces, it is quite possible to realize high quality and precision marking. The laser marking machine gives excellent results without warming and damaging the surface, which is especially important when, say, softer plastic is involved. The laser marking machine has various names that you may have encountered while researching the topic. Other names include cold laser engraving or a blue (or purple) laser beam. The reason for the machine’s multiple names is the light wave or UV light spectrum employed in its operation. This technology provides efficient engraving over different surfaces because it doesn’t heat the material.

This machine can accurately and beautifully engrave a design or an inscription you have imagined. The special ability of the UV beam is a final long-lasting print, which significantly facilitates work in further production or process. This type of engraving is used for various purposes. For example, the tiny and finely printed serial numbers on technical devices or cables, specifications on the device’s electrical adapters, decorative signs on various surfaces, or rather all the things that require ultra-fine printing.

Although the UV laser marking machine is known in the world of commercial and industrial printing, it is often confused with other machines of similar capabilities, such as the Fiber laser engraving machine and the laser etching machine. To simplify this, we will clarify what the difference is between these three machines. Laser printing discolors the original surface, while laser etching and engraving machines remove tiny portions of the printing area as their marks. Additionally, the difference between laser etching and engraving is the depth of the laser carvings.

Okay, since we’ve clarified this briefly, we will get down to the main things to consider when on a quest for a laser marking machine.

Components

This is self-explanatory. Each laser marking machine has the same main characteristics, but those also vary in different ways. For example, the power specified in watts (W), which can significantly improve and speed up the work process itself. In addition to this, it is important that the main components of the laser marking machine are of high quality to prevent frequent servicing. Some of the main parts of the machine, which you should definitely pay attention to, including laser source, control board, galvo scanner, g-theta lens, power supply, red light indicator, laser glass tube, and fume extractor. Each of these parts plays an important role in creating a satisfying end result.

Portability and size

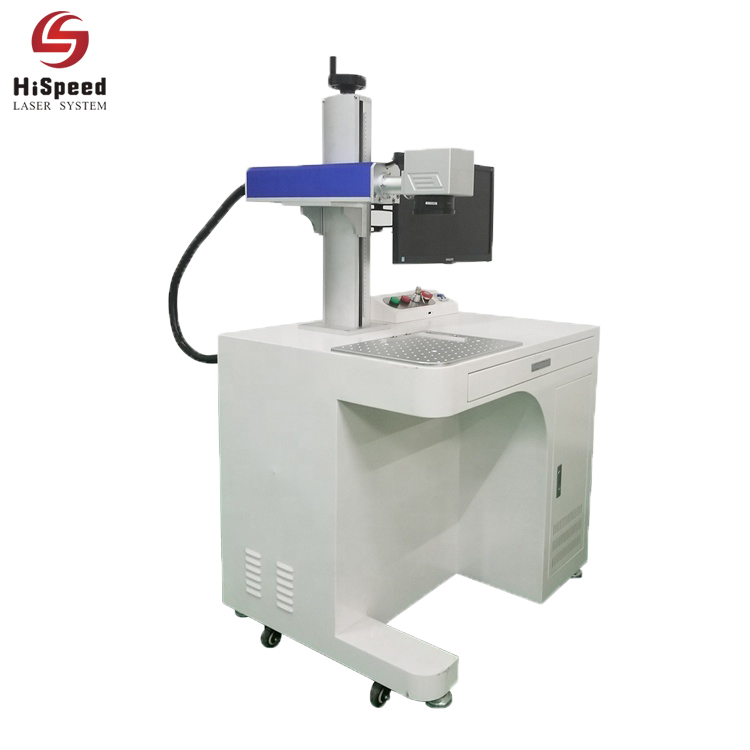

Depending on the kind of work you are planning, you can also choose the size of this machine. If your intention is to produce simpler prints and doesn’t need the highest precision possible, you can use mini versions of this machine. You can find one at hispeedlaser.com which is a perfect choice for laser marking on metal or plastic. The company we mention here is engaged in the production and sale of multi-type laser machines, both for marking and engraving, and does business with the whole world. You can contact them and ask for advice regarding a machine that would be ideal for your products. They will be very happy to help. The company has more than 10 years of experience in this business and credibility worth mentioning. This is supported by the fact that the company has worked with over 50 countries around the world and has a strong team of engineers who work every day to improve the quality of their products.

Working pace

https://www.youtube.com/watch?v=_tqQPuHES-E

If your company has a large or growing production, you will have a greater need for faster marking. Your production can have big problems, if, for example, the production line ejects items faster than the laser can mark them. This means that your production will be less time-efficient employing more time on one part of the production process, which is something you would probably want to avoid. Our advice in this regard would be to buy a machine that will be more powerful, say 20W, 30W, or 50W. However, it is worth mentioning that machines of higher power entail higher electricity consumption, therefore, higher electricity bills.

Price

Naturally, the price can be a crucial consideration. It is important to thoroughly research the conditions that companies or manufacturers offer. If you need more than one laser marking machine or you intend to become a distributor for some of the producers, you may be able to get a discount. In addition, companies often accept different payment terms and are flexible enough to ship a machine to you regardless of the shipping method. This, however, can contribute to the final price of the received machine.

Brand

Finally, buy machines from reputable manufacturers. We all strive for quality and durability and buying your machine from a reputable maker will buy you peace of mind in this regard. In general, this rule is not set in stone, but when it comes to technology, it is desirable to rely on names that have been in business for a long time and that specifically deal with the production of these types of machines.

We hope that we have clarified some important aspects when it comes to buying a laser marking machine in 2024. We think that this text can be useful especially if you are just starting a business and planning a smaller volume of production and labeling. Keep in mind that handling such machines requires certain knowledge and skill, so feel free to ask for help from professionals before you get comfortable using and handling them. For larger companies, we advise the mandatory work with experts or engineers who deal with the evaluation and selection of machines before procurement. This also involves hiring an expert to assess safety in the workplace. Now back to business and good luck with your search!

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024