What is the bursting strength property of textiles?

In the process of using textiles, they will be damaged by various forces, such as a tear, friction, tensile strength, bursting strength and so on. For some knitted fabrics with longitudinal extension and transverse shrinkage, it will often be subjected to the external force in the direction of the warp, zonal, and oblique at the same time when damaged. The force interacts with each other in all directions. If we use the tensile strength test or tear strength test, it is troublesome to test warp, zonal and oblique direction respectively. The Bursting Strength Test is a comprehensive embodiment of the fabric subjected to various forces, which is more close to the real situation.

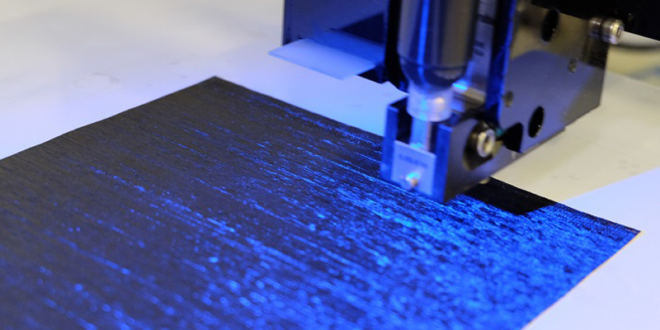

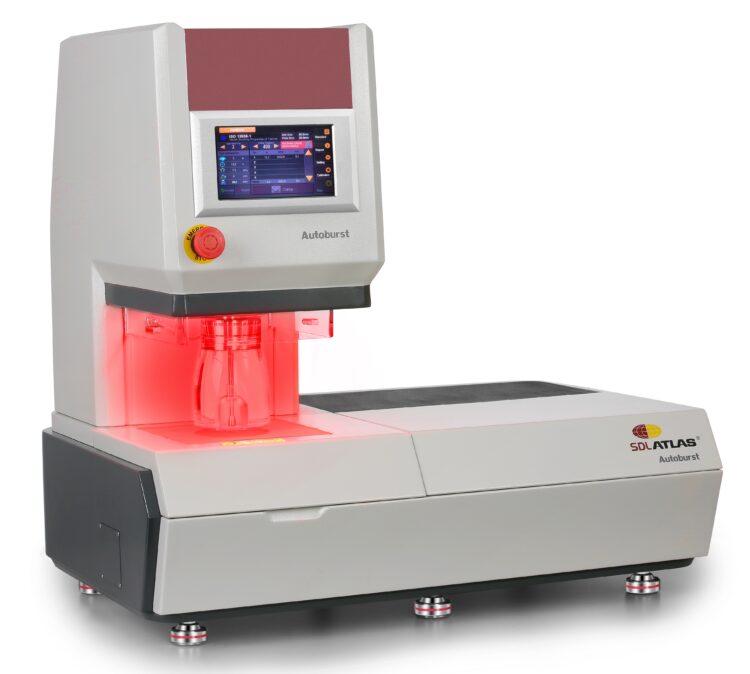

According to testextextile.com At present, there are three methods to test the bursting strength of the fabric: the steel ball method test, the hydraulic method test, and the pneumatic method test. The test result of the steel ball method is not stable, the pneumatic method test can be influenced by the air change, so it is commonly used in the bursting strength test of the parachute, and the most common is the hydraulic test.

What are the applications of fabric bursting strength property?

In the process of bursting, the force of the fabric is multi-directional, the weaving shrinkage rate of the fabric is large, the warp and the weft direction are close so that the bursting strength of the fabric is high. This is because the warp and weft yarns play a role at the same time on the bursting strength of the yarn. If the warp and weft yarn is different in the deformation capacity or the weaving shrinkage rate, the bursting strength may be very low due to the fact that the warp and weft yarn can not play the maximum function at the same time.

When testing the bursting strength, because the force of all sides of the textile is balanced, there will be no “pre-shrinkage” phenomenon, so it is especially suitable for knitted fabrics, tridirectional fabrics, and nonwovens, such as knee pads, socks, nylon bag, airbag, and parachute.

Wearing textiles such as knee pad and socks.

Knee pads have the advantages of tensile resistance, tenacity, comfortable touch, good air permeability and so on because they are mostly made of nylon, rubber, polyester fiber, polymer materials, cloth, and other different materials. Assist velcro for pressure and fixation to improve the stability of joints and muscles to keep them in place. In the course of exercise, proper use of knee pads can reduce joint and muscle injury caused by strenuous exercise or extensive stretching.

In the process of use, the knee joint has a relatively strong force on the knee pads, which is the main cause of wear and rupture of the knee pads. Therefore, the key factor to measure the durability of the knee pads is the anti-bursting strength performance of the fabric of the knee pads, which is generally made of elastic polyurethane fiber.

Nylon bags for daily use

A nylon cloth bag is a bag-shaped container made of nylon as the basic material. Nylon bag has the advantages of waterproof, light and tough, reusable and washable. Nylon cloth bag material is durable, and practicability very wide, such as supermarket shopping, household goods, outdoor sports and so on, more common nylon cloth shopping bag, heat preservation bag, portable backpack. In addition, the nylon bag is a kind of environmental protection bag, its material is polyamide fiber, which can decompose in the natural environment, no pollution to the environment.

The nylon is good toughness, wear-resistant, easy to wash, nylon bag is divided into the coating and no coating, the coating is elastic nylon cloth, no coating is inelastic nylon cloth. Elastic nylon is used for garment making and inelasticity for bag making. The nylon bag is often filled with a wide variety of articles, so the durability (bursting strength) of the nylon bag must be tested.

Airbag – functional textiles

The fiber used in the airbag is nylon 66. The silicone resin adheres to the dense fabric made of nylon fiber, which makes the fabric impermeability. Sewing two of these round fabrics into bags is an airbag (there are also fabrics that are not suitable for resin and airtight). In order to enable to discharge gas when the airbag contact with the occupant, a lot of exhaust holes are opened on the airbag. The combination use of the airbag and the seat belt can effectively guarantee driving safety.

When the airbag is started, because of the instantaneous inflation, the airbag will expand rapidly, and then collide with the human face or body, so there is a high requirement for the elasticity of the airbag, so it is necessary to test the bursting strength performance, airtightness, and son on of the airbag.

Parachute – functional textile

Because the material of 2/3 in parachute is composed of textile material, the performance of parachute is closely related to textile material, from the early silk, long-staple cotton, nylon silk, to the present polyamide fiber and ultra-high molecular polyethylene fiber, the performance of parachute is constantly improved and strengthened. In addition, the properties of the parachute are affected by the microstructure of the fabric to a great extent. Most of them use plain texture and increase the density of warp and weft or use thicker yarns to improve the strength of the fabric.

With the improvement of the strength of the parachute fabric, it has been applied in an increasing number of fields, from the traditional air-casting materials and personnel, and now in the field of aircraft, ship, and even space, so how to ensure that the bursting strength performance of the parachute is a key factor for the development of the parachute.

With the development of life and science and technology, more and more functional textiles appear, and the durability and safety are the first to be considered. The bursting strength property of a fabric is a necessary test item for some textiles. For knee pads, socks, nylon cloth bags, and other living textiles, the bursting strength mainly affects the durability of textiles, while for functional textiles such as airbags and parachutes, the bursting strength mainly affects the safety of textiles.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024