The advanced technology is making progress every single day. Fortunately, it seems that progress won’t stop soon. This also includes the improvement of 3D printing technology.

The traditional machining and injection molding is also a good way of work. People were using this method for ages. Yet, together with the improvement of technology, 3D print machines have brought a lot of advantages. Many businesses are now capable to turn a huge number of ideas into reality. For instance, you should check ltc-proto.com and see which products they printed until now. There you can see how all the pros that we will mention look in reality.

Anyway, we do not want to say that everything associated with 3D printing is perfect. There are also some cons that we need to mention. In that way, people will understand better how the entire 3D print industry works.

So, let’s get started.

1. Freedom of Design

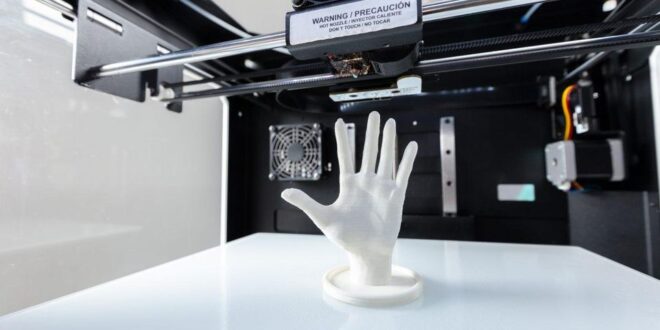

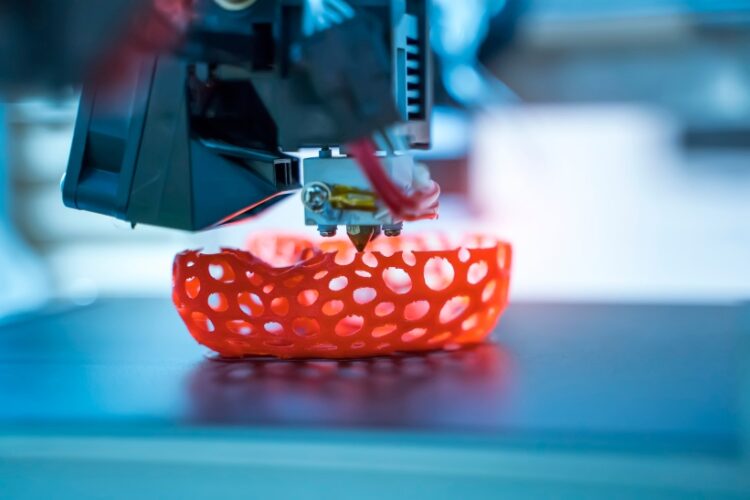

As we said, many ideas can turn into reality thanks to the newest technology. Machining and injection molding could not produce some complex geometry. Even if people were able to do that, they had to spend a lot more time. Some areas were simply not possible to the machine.

However, things have changed a lot together with the development of 3D printing technology. It supports various types of materials and people are not capable to make different types of geometry.

2. Faster Prototyping

Before the technology reached a new level, people needed to spend a lot of time to design prototypes. Well, we do not have that problem now. The prototypes can be produced for a couple of hours. Because of that, the entire design process became simpler and you won’t need to spend more than 1 day to design a product.

3. New Services

All business owners know how expensive inventory can be. It takes a lot of space that many startups are not able to afford. Yet, thanks to advanced technology, many businesses now can print on demand.

Let’s say that you designed something that most people would want to buy. You will probably sell it sooner or later. Yet, until then, you will have to ensure enough space to place it somewhere. Thanks to print-on-demand service, you will print only those things that a customer will buy immediately after you finish your work.

Despite that, 3D printing designs are housed as STL and Cad files. You can make the entire virtual library of all the parts that you previously printed. If the new customer asks for the same thing, your only task would be to use those designs once again when you need them.

Finally, there is one more benefit that businesses can get. As we said, you won’t invest a single penny in inventory or tooling. That allows you to change the designs without any larger costs. Thanks to this pro, you will save yourself from excess defective and outdated inventory.

4. Lighter/Stronger Parts of Product

Well, you already know that plastic is the primary material when we talk about this type of printing. This probably seems like an inferior material compared to aluminum and steel. Yet, people do not see that using plastic instead of metal is actually a great advantage. Luckily, we are there to explain.

Plastic is a lot lighter than the metals that e mentioned which makes the product itself a lot more flexible. Maybe you didn’t know, but many manufactured vehicles have switched to 3D printing parts. The reason for that is simple. It makes the car a lot lighter and that spends a lot less fuel.

5. Cost-Effective Benefits

We can’t say how much the entire printing project might cost. That depends on a lot of factors. Yet, when you look at the entire process, 3D printing is definitely a cost-effective method of work overall.

Before everything, the machine does the whole work. The manufactures will not have to spend a lot of their time on each step of the entire process. Despite that, the operator does not need to be nearby to move parts to a different machine or remove pick-outs. The 3D machine will do all those tasks itself. The only thing that workers will have to do is to set up everything and get back for a couple of hours when the process is finished.

6. Environment-Friendly

Well, 3D printing does not only bring benefits to businesses. The entire world can use the advantages of this way of work. Yet, this subject is not fully researched and we still wait for experts to share their analysis. Yet, something that we know is that this type of printing reduces waste reduction and fuel efficiency. More precisely, it can save some limited materials that we use and conserve energy.

We hope that this trend will continue to improve in the future.

Cons of 3D Printing

Our intention is not to be subjective. This industry has its disadvantages as well. We believe that our readers need to be aware of them as well.

A Bit Limited

As we said, this method of work and the type of machines allows people to work with almost every type of material. However, let’s repeat once again – “almost every material”.

You can find printers that will work with metal. Yet that doesn’t mean that each type of metal can be temperature controlled. This means that not each piece of metal will support printing. Things are not different when we talk about plastic. Some type of plastics is still not ready for designing and printing. However, we are sure that these things will change in the future. As we said at the beginning of the article, advanced technology improves daily.

Limited Build Volume

Most of the 3D printing machines come with the small build chambers. Let’s say that a customer demands a product that is huger than a build chamber. Will it be possible to print that type of product? Fortunately, it will. Yet, you will have to divide it into several different parts. After you do that, you will need to glue those parts together in post-processing. Unfortunately, this is the only moment when your costs may increase. Yet, this is not something that should worry you a lot.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024