According to the latest published reports, the industrial laser system market is projected to reach $14.52 billion by 2026. Over the years, we’ve seen the increasing applications of laser technology in various industries. Particularly, the rising demand for robotics and welding applications has played a key role in driving the overall demand for industrial laser systems.

These laser systems now play a vital role in the automotive industry, medical equipment marking, security technology, and ID industry, jewelry industry, smart coding for electronic components, engraving in the aerospace industry, and coding in the food and beverage industry.

In this article, we’ll look at the factors driving demand and how market players deliver industrial lasers systems to meet the requirements of customers while ensuring value addition.

The Flexibility and Time-Efficiency of Industrial Laser Systems

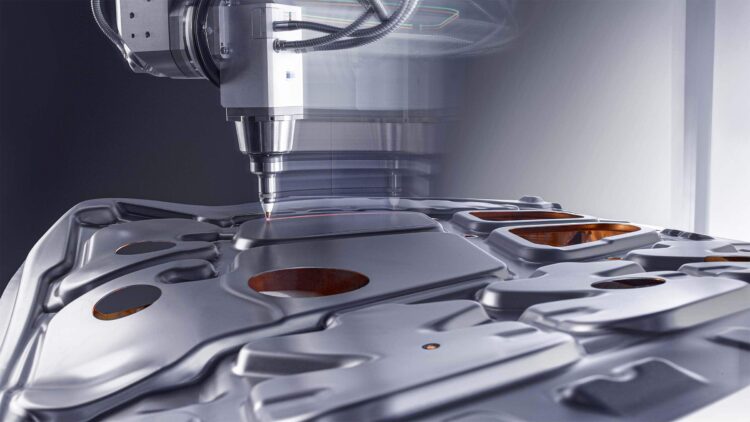

Industrial laser systems have continuously provided various advantages to companies of all sizes, including flexibility, improved productivity, and time-efficiency. Because of this, industrial laser systems are widely on-demand across various applications that rely on material processing such as construction, aerospace, automotive, industrial machinery and others.

According to Needham Laser, a leading global provider of laser engraving services, advancement in technology, such as the deployment of industry 4.0 and IoT, helps augment the time efficiency and cost-effectiveness of laser systems. This, in turn, provides growth opportunities to laser system manufacturers and laser material processing equipment companies.

Modern industrial laser systems also feature powerful usability features with a variety of options that are making it much easier for businesses to create perfectly matched systems. These provide a safe and clean solution that guarantees easy operation and efficiency. Ease of use has come a long way over the years and is now playing a huge role in driving demand across the market.

Evolving Consumer Market Growth

Lase systems and optics are increasingly being used in the production of consumer products like electronics and medical devices. Key market players are now delivering different industrial laser systems of different power capabilities to meet specific customer requirements. Various industrial sectors in the market are in high demand for various types of industrial laser systems.

This is because of the requirement of precise and accurate machining, engraving, or marking in manufacturing industries, which then facilitates markets that need more lasers. The surge in demand for consumer products that need specific laser processes, progress in automation, and fast industrial development is also playing a huge role in increasing demand.

The high demand in the medical industry for specific applications like cosmetic surgery, dentistry, and eye surgeries also means the market for industrial-grade laser systems will experience sustained development. While a lot has to do with growing consumer demands and personalized product growth, the industrial lasers systems market has to adapt fast to evolve.

Endless Application Options

Today, every conceivable laser application is achievable in no time, thanks to innovative industrial laser systems that combine different technologies like CO2 and fiber laser application. By offering flexibility by design, these systems enable businesses to enjoy endless application options with multifunctional features that users can switch depending on the application.

This ensures the highest level of productivity and processing quality. With more manufacturers offering multifunctional systems, the demand for these systems will increase as businesses get to enjoy maximum flexibility with multiple laser sources in a single system. In short, businesses can easily process a variety of different materials in one operation.

With even more possibilities being promised by manufacturers, businesses can enjoy easier and quicker expansion for their production and processes, time savings, and flexibility in everyday work. The ability to enjoy endless application options is a major driver of growth in the demand for industrial laser systems today.

Heavy Investment in Research and Development

Major market players are investing heavily in research and development of innovative industrial lasers to expand their business and strengthen their product portfolio globally. Because of this, manufacturers and distributors are adopting mergers and acquisition strategies, along with product innovation to attract major revenue now and in the near future.

As an example, FOBA AG developed the smallest and lightest fiber laser head in December 2019 for laser marking applications. There are many industrial laser market developments worth noting. There’s no doubt that the heavy investment in research and development is playing a key role in increasing demand for laser systems as market players gain a wider market footprint.

The Role of Distributors in Ensuring Value Creation

As demand for industrial laser systems continues to grow, manufacturers face one big challenge: finding the right distributors to partner with, to ensure value creation for customers and consumers alike. Market leaders want to be there for the end-user at every stage of the value chain. This is only achievable by improving supply and distribution chains.

Manufacturers looking to expand or gain a foothold in new markets need to have well-established distribution systems. Distributors play key roles:

- Turnkey Solutions for Custom Projects – Distributors can support clients with their customized projects. Whatever the industrial laser application project, the right distributor can help advise and support manufacturer services across different geo-locations. Working with the right distributor means benefiting through a global network and support, dedicated service, and solutions adapted to your business or product model.

- Optimization of Traceability Marking – With a fully interconnected permanent marking solution integrated into distribution systems, manufacturers can revolutionize traceability marking in their automated production and distribution lines. Distributors play a huge role in optimizing the identification and tracing of parts to ensure streamlined operations.

- Better Services With High-End Value – Innovative distribution helps transform the value chain and allows manufacturers to generate additional income while differencing themselves from competitors. From personalization in user interfaces to additional value products across distribution points, there’s a lot to gain from centralized distribution. It ensures better service delivery with high-end value while offering extraordinary business development opportunities.

Conclusion

As the demand for industrial laser systems continues to grow, we can expect to see more manufacturers identifying more market needs and offering simple and innovative solutions. Innovation and technology centers are constantly testing new solutions with clients, and getting the feedback they need to produce more reliable and proactive systems.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024