Not all CNC machining businesses are made equal. If you run a smaller CNC machining service business, here are a few tips to follow in order to maximize efficiency and productivity.

CNC machining is a brave new approach to the fabrication of parts, components, and products. It is fast, reliable, resource-efficient, consistent, and time and energy-efficient. Within the spheres of CNC machining, there is a multitude of industries, and service providers that have been birthed due to the diverse components and resources required. Go here if you are looking for more information about CNC machining and parts.

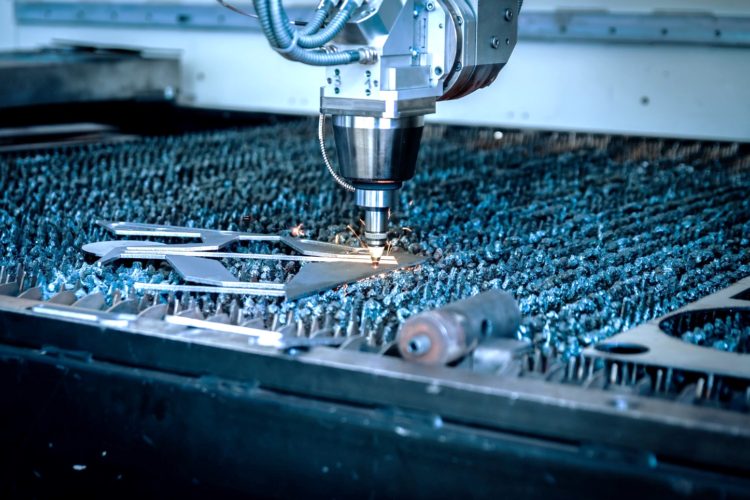

A CNC machining service produces parts, components, and finished products using machines that are computer-controlled. The computer is preprogrammed (using Computer-Aided Design software) to manipulate the machines that come in contact with the work material; which could be wood, metal, and sometimes glass. Businesses (much like yours) specialize in using these machines to achieve high-accuracy end products at a fraction of the time and manpower requirement that traditional means would expend.

A multitude of industries rely on CNC machined parts for their products and they include (but aren’t limited to): aerospace and aviation, consumer electronics, automobile, home appliance, jewelry, heavy implements, and petroleum exploration industries.

A booming industry, the growth rate for the CNC industry is expected to rise annually by double-digit percentages over the next five years.

Managing CNC services can be quite a daunting task, especially in the early stages. If your CNC business is relatively small, here are a few tips to consider that will help you maximize the efficiency of your resources.

Start small. This might be an obvious statement for a small CNC business but, in starting small, I mean you should scale every part of your trade to reflect its size. Lathes, for example, can cost anywhere between a couple thousand to tens of thousands of dollars. This is reflected in their size and work output. If you don’t have that much work demand and clients, consider investing in smaller (and therefore cheaper) machines to begin with. You can then acquire larger, more sophisticated machines when there is more demand for your services.

Rent out a smaller workspace. Before taking out a lease on that large workshop, carefully examine your trade to determine if that much space is really needed. For a small CNC service usually, a large garage can serve as the perfect improvise for a workshop. If (further down the line) it becomes imperative to move into a larger workspace (following an increase in the number of paying clients), you can then upgrade at little to no financial damage to your occupation.

Understand your recurring costs. Aside from the costs to the commercial activity that are incurred sporadically (machine purchase and the likes), there is also a slew of recurrent costs that arise monthly, weekly, or even daily. These may include utilities, maintenance costs, wages, etc. It is absolutely essential to understand the nature of those expenses and plan for them.

Figure out what kind of CNC service business you want to run. Usually, CNC professionals serve other trades (B2B service category). This means that they make products to sell to other businesses that need those products. But there are exceptions. Job shops generally take clients others and then build products to suit the specifications of the client. Product shops, on the other hand, manufacture products that were conceived in-house and sell those products either to businesses or end-users. Depending on your goals, available resources, physical location, and aspirations, a carefully considered choice should be made regarding whether you want to operate a job shop or product shop.

Consider automation. As we head into 2024, automation is going to be the new buzzword for machine shops and other industries that produce high-volume parts and products. If 2024 did nothing else, it showed the manufacturing world that the need for lights-out and automation-focused production shops is critical. Though the pandemic is beginning to slowly come under control, the lesson remains.

When you’re just starting to establish your machine shop, it’s a good idea to consider which parts of your shop floor can be automated. The more you automate, the better your capacity for production runs and the less downtime you face. With AI and software that learns as you use it, you’ll benefit from automated planned downtime, reduction in machine failures, the elimination of poorly scheduled maintenance times, and a production flow that is unparalleled.

Fictiv, a global CNC parts distributor, understands the importance of automation and a diverse supply chain. They expertly utilize a digital platform and a global manufacturing network to ensure their customers receive products on time, no matter where in the world they are located. Now, if you’re a small CNC business, a global network probably isn’t on your radar, but automation sure should be. No matter the size of your business, customers need manufacturers they can depend on, and automation is one of the best ways to provide that dependability.

It is also important to understand how CNC shops monetize. Usually, they make money selling machines parts at larger quantities. The economies of scale, as well as bulk payment for large orders, are what keep these kinds of businesses profitable.

Another point of note is how and how much to charge customers. The cost to the client of manufacturing their order usually depends on the kind of product ordered. There is usually a setup charge, a markup of between 22% to 34% on the cost of raw materials, machining costs charged by the hour (usually between $40 to $200 per hour), as well as miscellaneous expenditures that are tacked on to the total cost of manufacturing.

In order to understand how well (or badly) your commercial activity is performing, it is important to understand the generally accepted profit margins, especially for smaller CNC businesses. At the optimum performance, most CNC services businesses operate at a 10% to 15% profit margin. The only differentiating factor between larger and smaller businesses is the number of their work comments. This means, for example, that a smaller CNC service business with $600,000 in annual work income should make about $60,000 to $90,000 in pure profit (after salaries and other expenditures have been deducted of course).

An important aspect of any small service trades is an understanding of how to increase profits. More often than not, smaller CNC businesses increase their profits by diversifying their revenue streams and increasing the variety of products they offer. Slowly investing in new machinery for different kinds of production as well as personnel training towards taking new kinds of projects are a sure way towards making the trades more profitable.

If you want to keep your customers coming back, you can set yourself apart from the competition by getting industry certifications. Tags like ISO 9001 are certifications that tell discerning clients that your trades adheres to the highest CNC industry standards and this reinforces confidence in the mind of your potential (and current) customers.

Finally, it is important to understand how to promote your trades. In the fledgling stages, promotion is done or die when it comes to the survival of the business. Activities such as industry association meetings, networking events, and social media and internet marketing are proven platforms with which to achieve high conversion rates and attract new clients. Invest in a marketing professional to shape the outside perception of your commercial activity.

As I mentioned earlier in this piece, running a CNC commercial activity isn’t a walk in the park. It takes a careful balance of technical know-how, marketing savvy, and prudent management in order to ensure that your small CNC business is successful now and years into the future. It is a hands-on business that relies heavily on attention to detail and reputation perhaps more than anything else. Make sure to always evolve with the times, understand the direction that the industry is taking, and manage every aspect of the business properly to avoid wastage, redundancies, and leakages in any area of the occupation.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024