Welcome to our comprehensive guide on understanding the different types of CNC foam cutting machines. As a trusted and reliable source of information, we aim to provide you with valuable insights into the world of foam fabrication and how these cutting-edge machines can revolutionize your business.

In this article, we will delve into the various applications of CNC foam cutting machines across different industries.

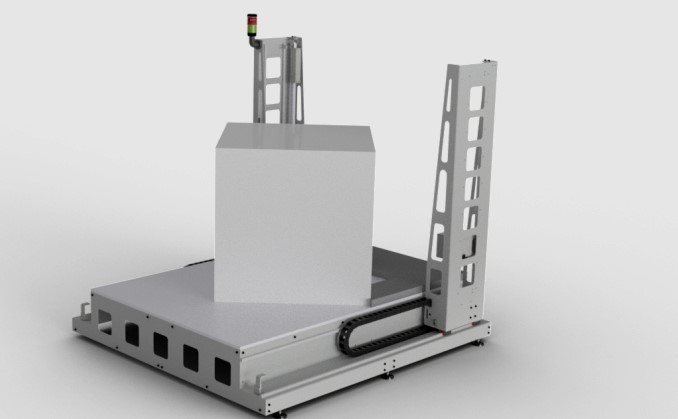

CNC Foam Cutting Machines

From automotive and aerospace to packaging and construction, these versatile machines have proven their worth in delivering precise and efficient results. Furthermore, we will explore the functionality and benefits that come with utilizing CNC foam cutting machines. By automating the cutting process, businesses can significantly improve efficiency, reduce waste, and enhance overall productivity. Choosing the right CNC foam cutting machine for your specific needs is crucial.

That’s why we’ll also provide you with expert tips and tricks to help you make an informed decision. Whether you’re a small business owner or a large-scale manufacturer, finding the perfect machine tailored to your requirements is essential for success. Lastly, we’ll share invaluable advice on maximizing the performance of your CNC foam cutting machines.

From maintenance tips to optimizing settings, our goal is to empower you with knowledge that will enable you to achieve optimal results and stay ahead in today’s competitive market. Join us as we embark on this journey through the world of CNC foam cutting machines. Let us be your trusted companion in exploring this innovative technology that has transformed countless businesses worldwide.

CNC Foam Cutting Machines ─ Types

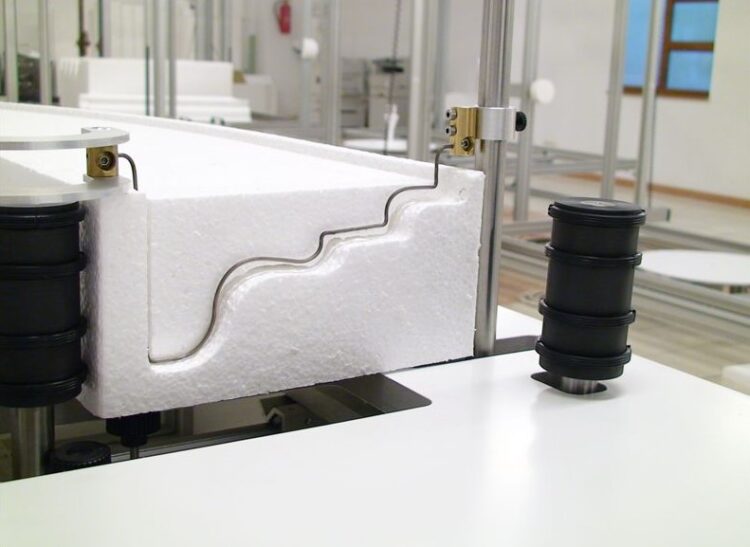

Before diving into the world of CNC foam cutting machines, it’s crucial to understand that there are several types available, each with its unique features and applications. The most common types include hot wire cutters, oscillating blade cutters, and router-based cutters. Hot wire cutters use a heated wire to melt through the foam, creating smooth cuts and intricate designs. Oscillating blade cutters employ a rapidly moving blade to slice through the material, ideal for thicker foams or more complex shapes. Router-based machines utilize a spinning tool to carve out designs from the foam block.

Hot wire CNC foam cutting machines are often used in industries where precision is paramount such as aerospace or architectural model making. They can create intricate 3D shapes with high accuracy and minimal waste. On the other hand, oscillating blade CNC foam cutting machines are perfect for businesses that deal with denser materials or require more substantial cuts like packaging or insulation industries. These machines can handle a variety of thicknesses and densities without compromising on speed or quality.

Router-based CNC foam cutting machines offer versatility in terms of design capabilities and material compatibility. They’re commonly used in sign-making, prop creation, and other industries requiring detailed carving work on foam materials. Understanding these different types of CNC foam cutting machines will help you determine which one best suits your business needs based on your specific applications and requirements. Remember that choosing the right machine can significantly impact your production efficiency, product quality, and overall business profitability.

CNC Foam Cutting Machines ─ Price

One of the most significant applications of CNC foam cutting machines is in the packaging industry. These machines are used to create custom packaging solutions for a wide range of products, from electronics to delicate glassware. The precision and accuracy offered by CNC technology ensure that each piece of foam is cut to the exact specifications, providing optimal protection for the packaged goods. This not only reduces the risk of damage during transit but also enhances the overall presentation and unboxing experience for the end customer.

In addition to packaging, CNC foam cutting machines are extensively used in the construction industry. They play a crucial role in creating architectural models and prototypes, as well as insulation materials. The ability to cut complex shapes and designs with high precision makes these machines an invaluable tool for architects and builders. Moreover, they help in reducing waste by utilizing every bit of material efficiently, thereby contributing to sustainable practices within the industry.

Beyond packaging and construction, CNC foam cutting machines find their application in various other industries such as automotive, aerospace, and entertainment. In automotive and aerospace sectors, they are used for creating seat cushions, headrests, armrests and other interior components with intricate designs. In the entertainment industry, these machines are utilized for creating props, sets and costumes with great detail. Thus, regardless of your business type or industry sector, investing in a CNC foam cutting machine can significantly enhance your production capabilities while ensuring cost-efficiency.

CNC Foam Cutting Machines ─ Benefits of Using

The functionality of CNC foam cutting machines is vast and varied, making them an indispensable tool in many industries. These machines operate using Computer Numerical Control (CNC) technology, which allows for precise, automated control of the cutting tools. This means that complex shapes and designs can be cut out of foam with extreme accuracy and consistency. The machine’s software can be programmed to cut exact specifications, reducing the chance of human error and increasing overall productivity.

One of the primary benefits of CNC foam cutting machines is their ability to improve efficiency in production processes. By automating the cutting process, these machines significantly reduce the time it takes to produce foam products. This not only speeds up production times but also reduces labor costs as fewer manual workers are needed. Furthermore, because the machine can be programmed to cut exact specifications, waste is minimized – a benefit that has both cost-saving and environmental implications.

Another significant advantage of CNC foam cutting machines is their versatility. They can handle a wide range of foam types – from soft foams used in upholstery to rigid foams used in construction or packaging. This makes them suitable for use in various industries including furniture manufacturing, automotive, aerospace, and more. Additionally, with advancements in technology, modern CNC foam cutting machines come with features like multi-tool capabilities and quick-change systems that further enhance their functionality and convenience.

How CNC Foam Cutting Machines Improve Efficiency

One of the most significant ways CNC foam cutting machines enhance efficiency in foam fabrication is through their precision and speed. These machines use computer-aided design (CAD) software to create detailed instructions for cutting, which eliminates the possibility of human error that can occur with manual cutting. This results in a high degree of accuracy, ensuring each piece of foam is cut exactly to specifications. Furthermore, CNC machines can operate at high speeds without sacrificing precision, allowing for faster production times compared to traditional methods.

Another advantage of using CNC foam cutting machines in foam fabrication is their ability to handle complex designs and shapes. Traditional cutting methods may struggle with intricate patterns or unique shapes, but a CNC machine can easily manage these tasks. The CAD software allows operators to input any design they wish, no matter how complex, and the machine will execute it flawlessly. This opens up new possibilities for product design and innovation in industries that rely on foam materials.

Lastly, CNC foam cutting machines contribute to efficiency by reducing waste. Because they are so precise, there’s less likelihood of making mistakes that result in unusable pieces of foam. This not only saves material costs but also helps businesses reduce their environmental impact by minimizing waste. Additionally, these machines require less physical labor than manual cutting methods, which can lead to increased productivity and lower labor costs over time. All these factors make CNC foam cutting machines an invaluable tool for any business involved in foam fabrication.

Choosing the Right CNC Foam Cutting Machine for Your Business

When it comes to choosing the right CNC foam cutting machine for your business, there are several factors you need to consider. The first is the type of foam you will be working with. Different machines are designed to handle different types of foam, so it’s important to choose a machine that can effectively cut the material you’ll be using. Additionally, consider the volume of work your business handles. If you’re dealing with large-scale production, a high-speed CNC foam cutting machine would be ideal.

Another crucial factor is the complexity of the designs you intend to create. If your business specializes in intricate designs and shapes, opt for a CNC foam cutting machine that offers advanced cutting capabilities and precision. Also, take into account the space available in your workshop or factory. Some machines require more room than others due to their size or operational requirements. Therefore, ensure that the machine fits well within your workspace without causing any inconveniences.

Lastly, don’t overlook the importance of after-sales service and support when choosing a CNC foam cutting machine for your business. This includes warranty coverage, availability of spare parts, and technical support services. A reliable supplier should provide comprehensive training on how to operate and maintain the machine efficiently as well as offer prompt assistance when needed. Remember that investing in a quality CNC foam cutting machine can significantly improve efficiency in foam fabrication while ensuring consistent results every time.

Once you’ve chosen the right CNC foam cutting machine for your business, it’s crucial to understand how to maximize its performance. Proper maintenance and operation can significantly enhance the efficiency and longevity of your machine. One of the first tips is to ensure that your machine is always clean. Dust and debris can accumulate over time, potentially causing damage or hindering the machine’s performance. Regular cleaning not only keeps your machine running smoothly but also allows you to spot any potential issues early on.

Another important aspect of maximizing the performance of your CNC foam cutting machine is understanding its capabilities and limitations. Overloading the machine or using it for tasks beyond its capacity can lead to premature wear and tear or even breakdowns. Therefore, always refer to the manufacturer’s guidelines regarding the maximum load capacity and recommended usage. Additionally, using high-quality cutting tools designed specifically for foam can greatly improve precision and reduce waste.

Lastly, investing in regular professional servicing can go a long way in maintaining optimal performance. While routine cleaning and basic maintenance can be done in-house, certain aspects like calibration or software updates may require expert attention. Regular servicing ensures that all parts are functioning correctly, software is up-to-date, and any potential issues are identified before they become major problems. Remember, an efficiently running CNC foam cutting machine not only delivers superior results but also saves time and resources in the long run.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024