Stainless steel-turned parts are fundamental to various industries due to their strength, corrosion resistance, and aesthetic appeal. These properties have turned stainless steel into an essential material in numerous applications, contributing to its widespread use in diverse sectors.

From automotive components to medical instruments and food processing equipment, the role of stainless steel is undeniable. It ensures the longevity of parts and meets the demanding hygiene standards required in some industries.

In a world of paramount quality, functionality, and appearance, stainless steel turned parts are the epitome of industrial excellence.

The Unique Properties of Stainless Steel

The distinctiveness of stainless steel lies in its unique combination of characteristics that make it ideally suited for turning processes:

- Strength and durability ─ Stainless steel’s inherent strength makes it resistant to wear and tear, even under extreme conditions. Its durability ensures that turned parts can withstand constant use without compromising performance.

- Corrosion resistance ─ Unlike other metals, stainless steel’s resistance to rust and corrosion makes it ideal for applications where moisture and chemicals are prevalent. This property is precious in industries like food processing, medical, and marine, where corrosion can lead to contamination or failure of components.

- Aesthetic appeal ─ Beyond its functional attributes, stainless steel is also appreciated for its sleek and shiny appearance. Its appeal makes it a preferred choice in industries where appearance matters, such as consumer electronics, automotive, and architectural applications.

- Hygienic properties ─ In sectors like the medical and food industry, the non-porous nature of stainless steel prevents the harboring of bacteria and contaminants, adhering to strict hygiene standards.

- Temperature resistance ─ Stainless steel can endure high temperatures without losing structural integrity. This resistance to heat makes it an ideal choice for components exposed to extreme thermal conditions, such as engine parts.

Applications Across Industries

- Medical industry ─ Stainless steel is integral to the medical industry and is used in various applications such as surgical instruments, implants, and medical devices. The corrosion resistance and hygienic properties of stainless steel make it the preferred material for manufacturing tools that come into contact with biological materials and must be sterilized regularly. Precision-turned parts like scalpel handles, orthopedic screws, and dental instruments exemplify how stainless steel contributes to healthcare, ensuring durability and patient safety.

- Food processing ─ In food processing, stainless steel turned parts are used for components that must withstand acidic substances, moisture, and extreme temperatures. Its resistance to corrosion and bacterial growth makes it an ideal material for applications that require strict hygiene standards, such as mixing tanks, valves, conveyors, and cutting blades. From farm to table, stainless steel is essential in maintaining the quality and safety of food products.

- Automotive ─ Stainless steel is ubiquitous in the automotive industry, where it is used to create high-quality, durable parts that must withstand vibration, weather conditions, and physical stress. Turned components such as engine components, exhaust systems, and suspensions benefit from stainless steel’s strength and temperature resistance. Its aesthetic appeal also makes it a favorite for external fittings and trim, adding a touch of sophistication to vehicles’ appearance.

- Oil and gas ─ In the demanding environment of the oil and gas industry, stainless steel turned parts are essential for ensuring reliable and efficient operations. Components like valves, fittings, and drilling equipment must resist corrosion from harsh chemicals, extreme pressure, and volatile temperatures. Stainless steel’s unique properties make it a vital material for applications where failure is not an option. Its ability to endure the harshest conditions makes stainless steel an irreplaceable part of the energy sector, reflecting resilience and innovation.

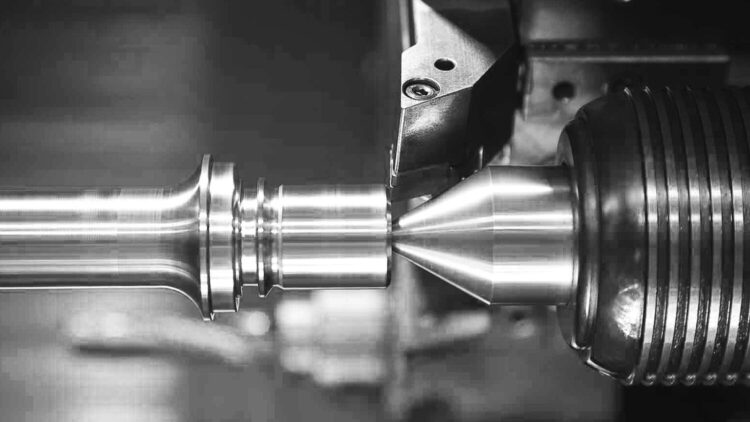

Swiss Machining Stainless Steel ─ Crafting Precision in Modern Industries

Swiss Turning Stainless Steel epitomizes the intersection of technology, material science, and craftsmanship. This process, vital in modern manufacturing, hinges on an in-depth understanding of the unique properties of stainless steel (Material), stringent quality control measures (Quality Assurance), the ability to maintain efficiency in high-volume production (High Volume Efficiency), and unceasing commitment to embracing future technologies (Future-Ready).

The following sections will unfold how these aspects form a cohesive, state-of-the-art manufacturing process.

Material

Stainless steel, a complex alloy, offers unique machining challenges due to its hardness, toughness, and resistance to wear and corrosion. In Swiss turning, understanding these properties is crucial. Engineers must select the proper grade of stainless steel, balancing factors like machinability, strength, and corrosion resistance.

Careful control over cutting speed, feed rate, and tool geometry is required. Sophisticated cooling and lubrication techniques are often utilized to minimize wear and maintain accuracy.

Quality Assurance

Quality control is paramount in stainless steel Swiss machining. The process employs real-time monitoring, using sensors and optical inspection systems to ensure that every part meets specifications. Tight tolerances down to micrometers are achieved through state-of-the-art metrology equipment.

Each production stage is carefully monitored, and statistical quality control methods are employed to ensure consistent performance across large production runs.

High Volume Efficiency

Swiss machining is not only about precision but also about efficiency in high-volume manufacturing. Machines are often set up to perform multiple operations simultaneously, significantly reducing cycle times.

Automation in loading and unloading, combined with robust machine design, enables continuous operation with minimal downtime. Process optimization techniques are regularly applied to maintain the production rate without sacrificing quality.

Future-Ready

Swiss machining of stainless steel turned parts continuously evolves, embracing emerging technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and Industry 4.0 standards. Integration with these digital technologies enables better process control, predictive maintenance, and adaptable manufacturing setups.

Collaborative research with academic institutions and technology companies drives ongoing innovation, ensuring that Swiss machining remains at the forefront of manufacturing excellence.

In summary, stainless steel turned parts are indispensable in various modern industries, from medical and food processing to automotive and oil and gas. Their unique properties, such as strength, corrosion resistance, and aesthetics, make them ideal for various applications that require durability, hygiene, and longevity.

It combines the unique material properties of stainless steel with stringent quality control measures, high-volume efficiency, and future-ready technologies such as AI and IoT. SABNER, as a leading supplier of turned parts, plays a vital role in providing these high-quality, precision-engineered components, contributing to the progress and resilience of modern industries.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024