Industrial machinery relies heavily on valves. They’re used in a broad range of industries. A valve’s primary function is to allow for the regulated flow of various materials. An inner layer that can be opened and closed makes up a valve. Industrial valves have developed considerably with the inception of new mechanical innovations. Industrial valves are currently more efficient than they have ever been.

Many different types of industrial valves are being developed, each with its own set of features. Valve production used to be primarily done with steel, but now it is also done with different substances. Material selection is based on the valve’s intended use. This article will give you an overview of several industrial valve kinds. Let’s get to it!

1. Toggle Valve

The design of a toggle valve is comparable to that of a ball valve, but the design is slightly different. The toggle valve differs from a ball valve in its capacity to adjust flow. It is mostly used to adjust the interior force of fluid to ensure a level flow. Toggle valves come in a variety of dimensions and structures, depending on their use.

2. Ball Valve

Ball valves are a common selection for domestic applications, but they are also widely utilized in industry. Ball valves get their name from the fact that they contain a disk within that is structured like a ball. To halt the flow, the disk blocks the valve venting and vice versa. Ball valves are used to manage the flow of various states of matter such as gas, liquid, and semi-liquid.

Ball valves have the benefits of being able to work at both very high and very low temperatures. Ball valves are also ideal for managing gaseous flow because of their excellent sealing. Moreover, ball valve China from en.siovalve.com offers the best in the industry and are really dedicated to ensuring that they are cost-efficient and consumer-friendly.

Fastening ball valves may at times feel quite cumbersome since it needs to be handled by experts. However, the best part about this is that if your firm needs better fixing, you can employ a robotic arm to fasten them for you.

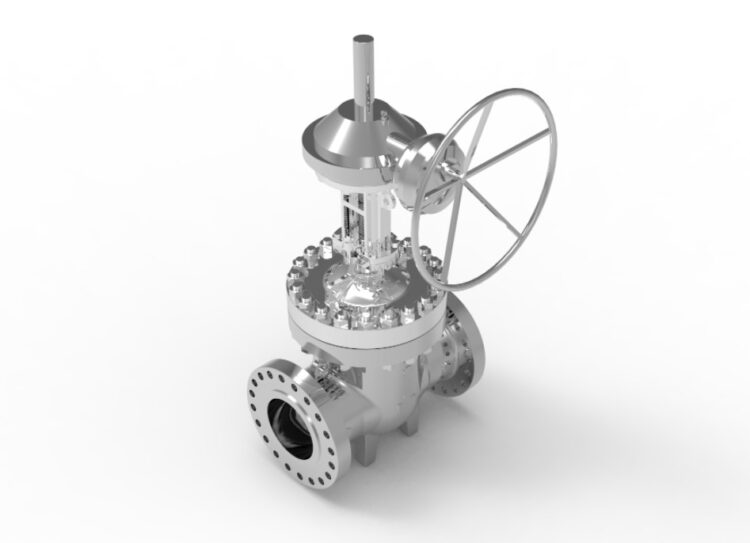

3. Gate Valves

Dissimilar to ball valves, gate valves are more commonly used in industrial settings than in dwelling settings. A gate valve is a type of liquid valve that is larger than a ball valve. The fluid flow is controlled by a perpendicularly elevated knob. To control the flow, they contain an interior lid that unlatches and closes. These valves have a metallic interior membrane to keep high-density liquids contained. However, the inside lids of some gate valves meant to handle lighter fluids are made of plastic.

Gate valves have a perpendicular rod that is attached to the hinge. On each side of the hinge, there are two stretched straight rods. Since the parallel rods do not allow any gaps, the gate valves can’t be used to control the flow. They can only permit flow commencement and termination.

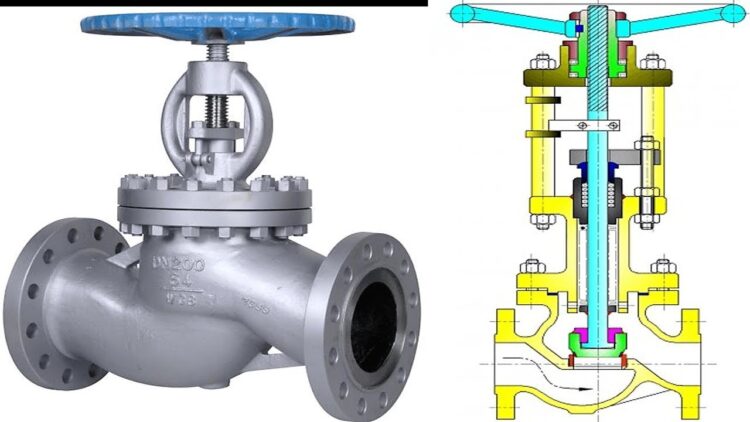

4. Globe Valve

Globe valves are widely utilized in a variety of sectors due to their versatility. Their shape is similar to that of gate valves, but their functioning is subtly different. Within a globe valve, there is a perpendicular shaft that is attached to a hinge that may be whirled by spinning the rod. The hinge is situated between two parallel rods that overlap. Because of this overlaying, the system for regulating the flow has a cushion.

Globe valves’ industrial prominence stems in part from their simple operation and ease of use. Gate valves have less resistance between the parts than other varieties, making them excellent for repeated use. The gate valves are also made of sturdy material, which adds to their robustness. The time it takes to open and close a gate valve, on the other hand, is not the fastest.

5. Check Valve

Check valves have a restricted range of operation in that they only enable liquid to flow in one direction. It’s for this reason that they’re also known as Non-return Valves. They’re commonly utilized in processes where a fluid’s reverse flow causes adverse circumstances. As a result, they’re widely employed in the petrochemical and water management industries.

Check valves have a great deal of pressure resistance. They use heavy-duty metallic lids to prevent the liquid from flowing backwards. The force threshold of a check valve is also determined by the quality of the check valve’s fabrication.

6. Butterfly Valve

The term stems from the valve’s form. They usually have a two-branched shaft that can be turned to enable or prevent liquid flow. They manage flow as well, however, their powers are limited when contrasted to globe valves. A butterfly valve’s metallic plate is angled at right angles with the flowing substance. Butterfly valves are used to control the flow of both liquids and gases.

The Bottom Line

Every valve has advantages and disadvantages. As a result, deciding which one is the most effective is difficult. In the industrial sector, all of the varieties of valves described here are the most common. To ensure that your employees are aware of which valves to apply, you can use 3D simulation screens to train them on the appropriate application of each. All the best!

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024